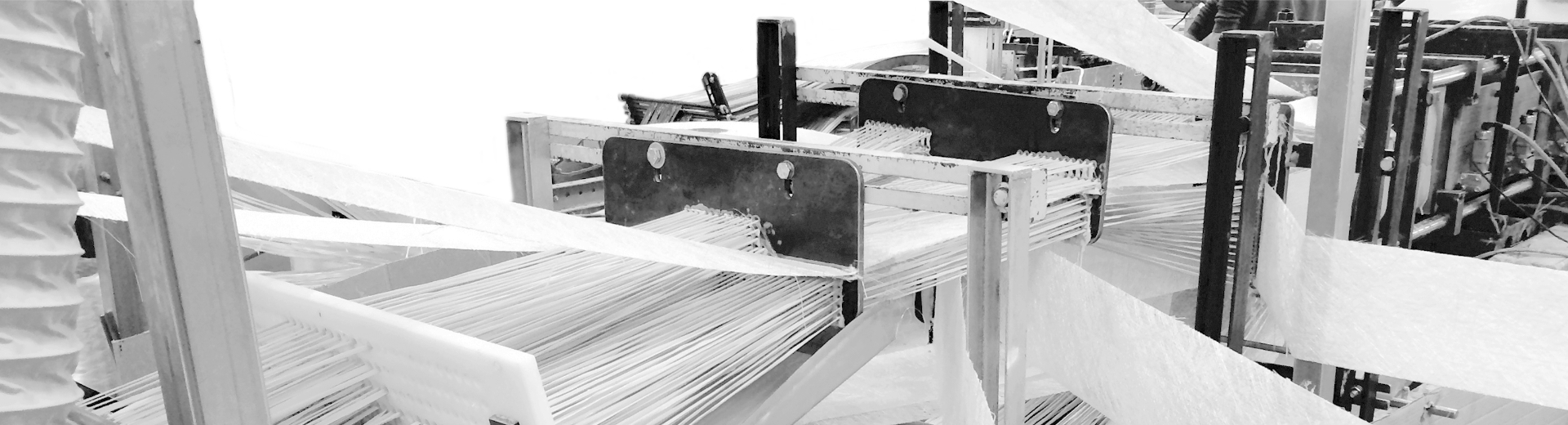

Pultrusion and pullwinding

continuous fiber reinforced plastics production technology

We produce composite profiles using continuous pultrusion and pullwinding technology, which, thanks to stable quality and high productivity, represent the most economical production of composites.

Our profiles based on reinforcing fibers and resins are characterized by unique properties such as high strength, rigidity and low weight.

We produce profiles from composite materials on 8 pultrusion lines in the production plant in Tišnov (Czech Republic) and on another 15 lines in the production plant in Montendre (France). In cooperation with our customers, we have developed hundreds of products for industrial, agricultural and leisure time applications. Thanks to experience, cooperation with raw material suppliers and especially the focus on the development of new products, we can offer our customers unique competitive solutions.

We are certified according to ISO 9001 and ISO 14001.

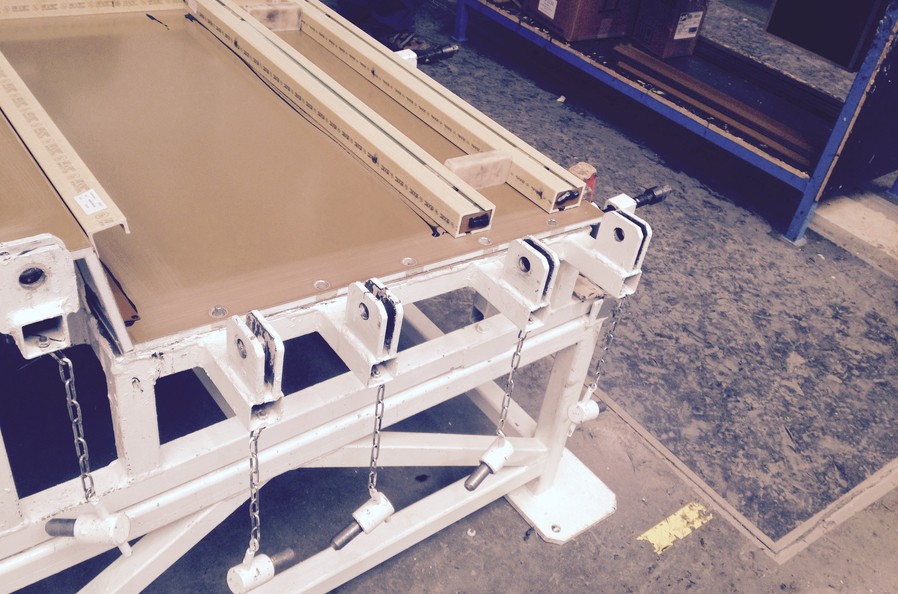

Joining profiles and assembling systems

creation of light and strong structures

LONG - TERM EXPERIENCE WITH BONDING COMPOSITES

If you do not need detachable joints, then composites and adhesives are materials for each other. With the right design, choice of materials and the right joining technique, glued joints are stronger and more fatigue resistant than mechanical joints. Glued joints save weight and, thanks to the absence of holes (which weaken the structure and can facilitate the penetration of moisture) and easier assembly, can also bring significant labor savings and shorter production time.

We have experience with bonding composite profiles to various materials in construction, automotive, telecommunications or sports applications, and we are happy to help find a balance between the required performance properties and processing parameters.

MECHANICAL FASTENERS

Especially in cases where it is difficult to ensure the correct procedures and process parameters of gluing or if it is important to be able to replace part of the system, mechanical fasteners will find application.

In cooperation with specialists in design and construction, we are able to offer various walkable and mobile footbridges and bridges, guardrails, ladders and complete structures.